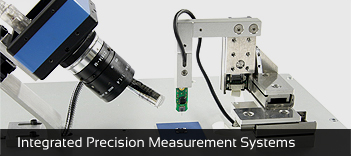

To meet the needs and requirements of the clients, we manufacture, supply and trade a quality array of Integrated Precision Measurement Systems. The Integrated Precision Measurement Systems we offer is suitable for various applications.

Integrated Precision Measurement Systems

Inspection Automation Systems

We offer an extensive range of Laser measurement Systems that are appreciated amongst the clients for optimum quality and durable standards. Our entire product range is quality assured in nature and are functionally advanced. Laser based Precision Inspection System are used in industrial and commercial sectors.

Features

- Accuracy upto 1 MIRcon

- High Speed Online Measurement upto 500 Components/Minute

- Thickness Measurement

- Sorting and packing based upon measurement output

- Interfacing Laser output to existing process instrumentation

- Largest Sensing Distance

Sensor Measurement Systems

We offer an extensive range of sensor based measurement Systems of highest quality and durability. Our entire product range is quality assured in nature and are functionally advanced. The following sensors based integrated measuring systems can be provided.

- Inductive Sensor

- Capacitive Sensor

- Magnetic Sensor

- Photoelectric Sensor

- Ultrasonic Sensor

- Precision measuring switches

Hybrid Measurement Systems

Hybrid Precision measurement Systems deploy a mix of lasers, sensors , Machine Vision to achieve complex measurement requirements.

Features

- Integrated control for all sensors

- Simple User interface for operations

- Integration with existing manufacturing process control

- High Speed online system

Desktop Measurement Systems

Owing to years of experience in the industry, we offer an exceptional range of Desktop Measurement Systems that are acclaimed among the clients for optimum quality and durable finishing standards. They are dimensionally accurate in nature and have smooth finishing. Our entire product range is used for inspecting different software components and is delivered as per the requirement. Desktop measurement systems are standalone easy to use systems

Features

- High accuracy Dimensional check at 10 Microns

- Hatch angle measurement for bores

- Contour Inspection

- Sample Profiling

- Sample Bar Code verification

Printing Verification Systems

Enriched with vast industrial experience in the industry, we offer varied range of Printing Verification System that is acclaimed among the clients for optimum quality and smooth operations. Our entire product range is functionally advanced and is in adherence with set quality standards.

Machine Vision system for Printing Verification using advanced technology for detecting printing defects like:

- Blob

- Smurging

- Overlap

- Ink fade out

- Blotting

- Missing Print

- External Particle on Print Area

Frequently Asked Questions (FAQ's)

An Integrated Precision Measurement System is a comprehensive setup that combines various measurement equipment and technology to provide highly accurate and repeatable measurements. These systems are utilized across different industries to ensure product quality and process optimization.

These systems function by integrating different measurement devices such as coordinate measuring machines (CMMs), laser scanners, optical comparators, and sensors. They collect data from the physical world and process it using specialized software to deliver precise measurements and analyses.

Industries such as aerospace, automotive, electronics, manufacturing, medical devices, and precision engineering greatly benefit from these systems for tasks like quality control, inspection, and reverse engineering.

Key components include measurement instruments (CMMs, laser scanners, etc.), data acquisition hardware, calibration tools, and analysis software. Each component is crucial for ensuring accurate and reliable measurements.

These systems can perform dimensional measurements, geometric tolerances, surface roughness measurements, and more. They can measure attributes like length, shape, feature, and surface texture with high precision.

Calibration is vital as it ensures that the measurement instruments provide accurate and dependable data. Regular calibration against known standards is essential to maintain measurement accuracy and repeatability.

Software is essential for data processing, analysis, and reporting. It aids in converting raw data from measurement devices into meaningful information, enabling detailed inspection reports, statistical analysis, and quality control.

Yes, many of these systems can be automated to enhance efficiency and reduce the potential for human errors. Automated systems can perform repetitive measurements quickly and accurately, integrating with production processes for real-time quality control.

Common applications include dimensional inspection, first article inspection, reverse engineering, tool and die making, and quality assurance in production lines.

Integrated Precision Measurement Systems utilize advanced technologies like 3D laser scanning and multi-sensor integration to handle complex geometries and a wide range of materials. They can accurately measure intricate shapes and surfaces that are challenging for conventional measurement tools.

Benefits include improved measurement accuracy, reduced inspection times, enhanced product quality, traceable measurement data, and the ability to detect defects early in the manufacturing process.

Challenges can include high initial costs, the need for specialized training, integration with existing systems, ensuring controlled environmental conditions (temperature, vibration), and keeping up with regular calibration and maintenance.

These systems are highly reliable when properly maintained and calibrated. Regular maintenance, software updates, and adherence to operating procedures are crucial to ensure their durability and accuracy.

Support can include installation and setup assistance, operator training, regular maintenance services, software updates, calibration services, and technical support from the manufacturer or specialized service providers.

Yes, Integrated Precision Measurement Systems are often modular and scalable. They can be upgraded with new sensors, software upgrades, additional measurement capabilities, and improved data processing tools to meet evolving needs.