We are into manufacturing, supplying, trading an extensive range of Machine Vision Automation Systems. These products are recommended by the clients for their precise use.

Machine Vision Automation Systems

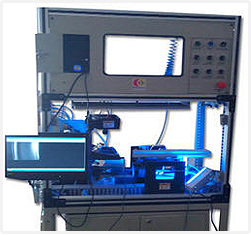

Inspection Automation Systems

We are amongst the reckoned names in the industry, offering functionally advanced range of Machine Vision Inspection Automation Systems that are durable in nature and performance oriented. They are sturdy in construction and are abrasion resistant in nature.

Technically Superior Design allows for:

- Very high rate of Inspection upto 600 Components

- Accuracy of upto 10 micron

- Easy User Interface( Customer specified Regional Language)

- Plug and play (Unskilled labor can operate)

Customized Solutions can be provided:

- As standalone system with feeder and sorter

- For Missing Operation Detection and sorting

- To integrate into existing manufacturing line thereby eliminating separate process for inspection.

- To integrate Machine Vision into existing Machine

- Refurbish existing Machine Vision Systems for any new adaptations

- Cutting Tool inspection for Machine Tools

Sorting Automation Systems

We offer an extensive range of high speed Sorting Automation Systems that are configured with advanced technologies and modern tools. We offer them in varied standard technical specifications and are automated as per the preferences of our clients. We design and implement Machine Vision Based Sorting Automation system for.

Component Sorting based upon

- Color

- Size

- Shape

- Legend (i.e., Batch No, Expiry Date, Model no, Logo etc)

- Bar Code, 3D Matrix, QR Code

- Integrated Packing after sorting

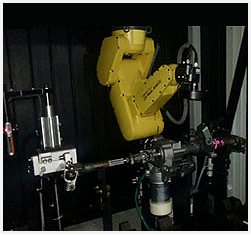

Robot Guided Vision Automation Systems

Quality being the main concern, we offer functionally advanced range of Robot Guided Vision Automation Systems. They are delivered in standard specifications and are power efficient.

Robot Guided Machine Vision Automation for inspection and qualification of components can be deployed for

- Inspecting components of varying dimensions

- Can accommodate more number of products with varied dimensions

- High Speed and Adaptable

- Online Assembly Inspection

- Multiple components can be inspected in one inspection cycle

Printing Verification Systems

Enriched with vast industrial experience in the industry, we offer varied range of Printing Verification System that is acclaimed among the clients for optimum quality and smooth operations. Our entire product range is functionally advanced and is in adherence with set quality standards.

Machine Vision system for Printing Verification using advanced technology for detecting printing defects like:

- Blob

- Smurging

- Overlap

- Ink fade out

- Blotting

- Missing Print

- External Particle on Print Area

Frequently Asked Questions (FAQ's)

Machine Vision Automation System utilizes cameras and image processing software to inspect, analyze, and interpret visual data from the real world. These systems are employed to automate visual inspections and measurements, thereby enhancing efficiency and accuracy in manufacturing and quality control processes.

Machine Vision System operates by capturing images of objects using cameras, processing these images with specialized software to extract relevant information, and then utilizing this information to make decisions or take actions. The process typically involves image acquisition, preprocessing, feature extraction, and analysis.

Industries such as automotive, electronics, pharmaceuticals, food and beverage, packaging, and manufacturing widely utilize Machine Vision Automation Systems for applications like quality control, assembly verification, defect detection, and sorting.

Key components include cameras, lighting, lenses, image capture boards, processing hardware, and vision software. Each component plays a crucial role in ensuring accurate image acquisition and analysis.

Machine Vision Systems typically employ industrial cameras, which can be area scan cameras, line scan cameras, or 3D cameras, depending on the application requirements. These cameras offer high resolution, fast frame rates, and durability.

Lighting is critical in a Machine Vision System as it directly impacts the quality of the captured images. Proper lighting ensures that features of interest are clearly visible, which is essential for accurate image analysis. Different lighting techniques, such as backlighting, ring lighting, and diffuse lighting, are employed based on the application.

Image preprocessing involves enhancing the captured images to improve their quality and make feature extraction more effective. This can include techniques such as filtering, normalization, contrast adjustment, and noise reduction.

Yes, Machine Vision Systems can be integrated with other automation systems like robotic arms, conveyor belts, and PLCs (Programmable Logic Controllers) to provide a fully automated solution for various industrial applications.

Common applications include defect detection, assembly verification, object recognition, barcode and OCR (Optical Character Recognition) reading, measurement, and alignment.

Machine Vision Systems employ advanced algorithms and machine learning techniques to adapt to different object types and conditions. They can be trained to recognize and analyze various shapes, sizes, colors, and textures, making them versatile for diverse applications.

Benefits include increased production speed, improved product quality, reduced labor costs, enhanced accuracy, and the ability to perform inspections that are difficult or impossible for human operators.

Challenges can include selecting the right components, setting up proper lighting, calibrating the system for accurate measurements, and ensuring that the system can handle the specific requirements of the application. Additionally, integrating the system with existing automation infrastructure can be complex.

Machine Vision Systems are highly reliable when properly designed and maintained. Regular calibration, software updates, and routine maintenance of hardware components are essential to ensure ongoing accuracy and performance.

Support can include installation services, training for operators and technicians, software updates, troubleshooting assistance, and regular maintenance services provided by the manufacturer or specialized service providers.

Yes, Machine Vision Systems are often modular, allowing for upgrades and expansions. This can involve adding more cameras, improving processing power, upgrading software, or integrating additional sensors to enhance capabilities.